Equipment

We use SolidWorks to design or re-engineer custom projects.

Quality Dept. Equipment: ISO 9001 QMS

- NBrown & Sharp CMM with Pcdimis software & a Renishaw 5-axis measuring head.

- NMitutoyo CRYSTA-Apex S 574 CNC CMM XYZ Range 500x700x400mm

- NTemperature control rooms using Air Dryer (IDG30LA-03).

- NTesa height gauge

- NA full set of measuring equipment is maintained in our QA Dept.

- NHardness tester

- NSurface roughness testing

- NGauge blocks, micrometres, and verniers

- NMicro Scopes

3 D Printing Dept

SLA 3 D Printer and scanner 120mm x 150mm x 150mm.

The SLA process starts with a 3D printer containing a tank of UV-curable resin. When a print begins, the build platform is submerged in the tank and a laser beam traces the contours of a part, solidifying the layer of liquid resin. Once the layer is complete, the build platform is lowered, making room for the next layer SLA (stereolithography)

CNC Turning Department

- NDoosan Puma GT 2100 with 65mm bore (purchased March 2017)

- NDoosan Lynx 2100 purchased Feb 2018

- NMori Seiki CL 150 turning centre

- N3 x Hyundai HIT 18S turning centres with Siemens control (70mm in the bore) (validated for medical production)

- N1 Megga saw 250. Automatic band saw.

Center Lathes

- NMorton FEL 1660 Center lathe

- NSwift Cut FEL 1440 Center lathe

- NIMA Bl-1230 center lathe

CNC Milling 3 Axis with 4th, 5th Axis attachments

- N3 x Hurco i10's

- NHurco. Vm 20i

- NHurco. Vmx 30

- NHurco. Vmx 24

- NHardinge. Vm600 (5th Axis 120mm chuck)

- NHardinge. VM600

- NHurco. Hawk

- N2 Gate Eclipse 2 axis CNC. machine

- N10 Conventional Bridgeport milling machines with 3 axis. DRO’s

CNC Surface Grinding.

2 x Andmar YSG-1224TS with Speedtec control it has a capacity of 300mm x 600mm with a fine pole magnetic chuck and automatic dressing & compensation.

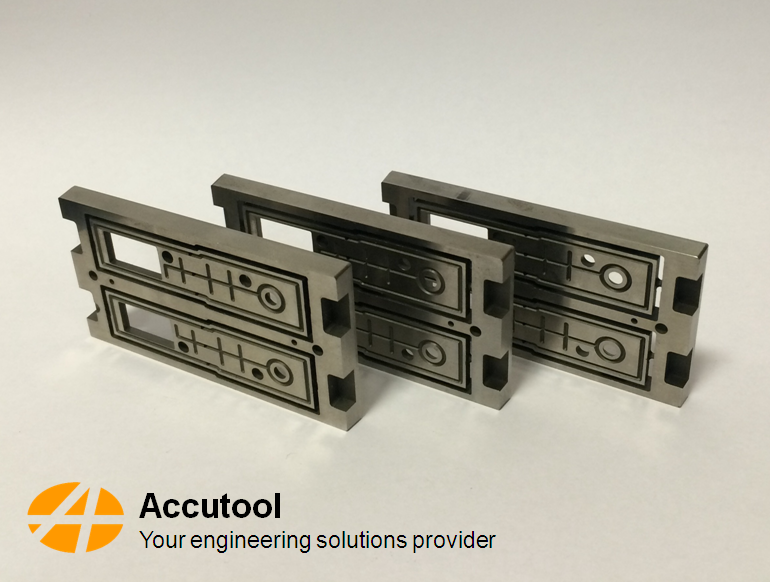

CNC Wire Spark Erosion

The EDM process complements our existing range of CNC milling and turning capabilities and allows us to create tapers, small radii, complex contours, and surface finishes within tolerances of just a few µm, either as a stand-alone subcontract offering or as part of supply-complete projects.

1 Die Sinker Deckel DE10

1 manual Jones & Shipman surface grinder

Laser Cutting and Laser Marking

2 off GCC Laser Pro 450 capacity 450mm x 350mm & 6mm thick plastic

1 Laser Pro C180

CNC Router

Fabrication & Welding Dept

- NHACO 100 tonne CNC Press break

- NHACO 3 meter Guillotine with digital control

- NCorner Notcher & hole puncher

- NMiter saw.

- N8 welding machines including MIG & TIG

- NGrinding and polishing to cleanroom standards.

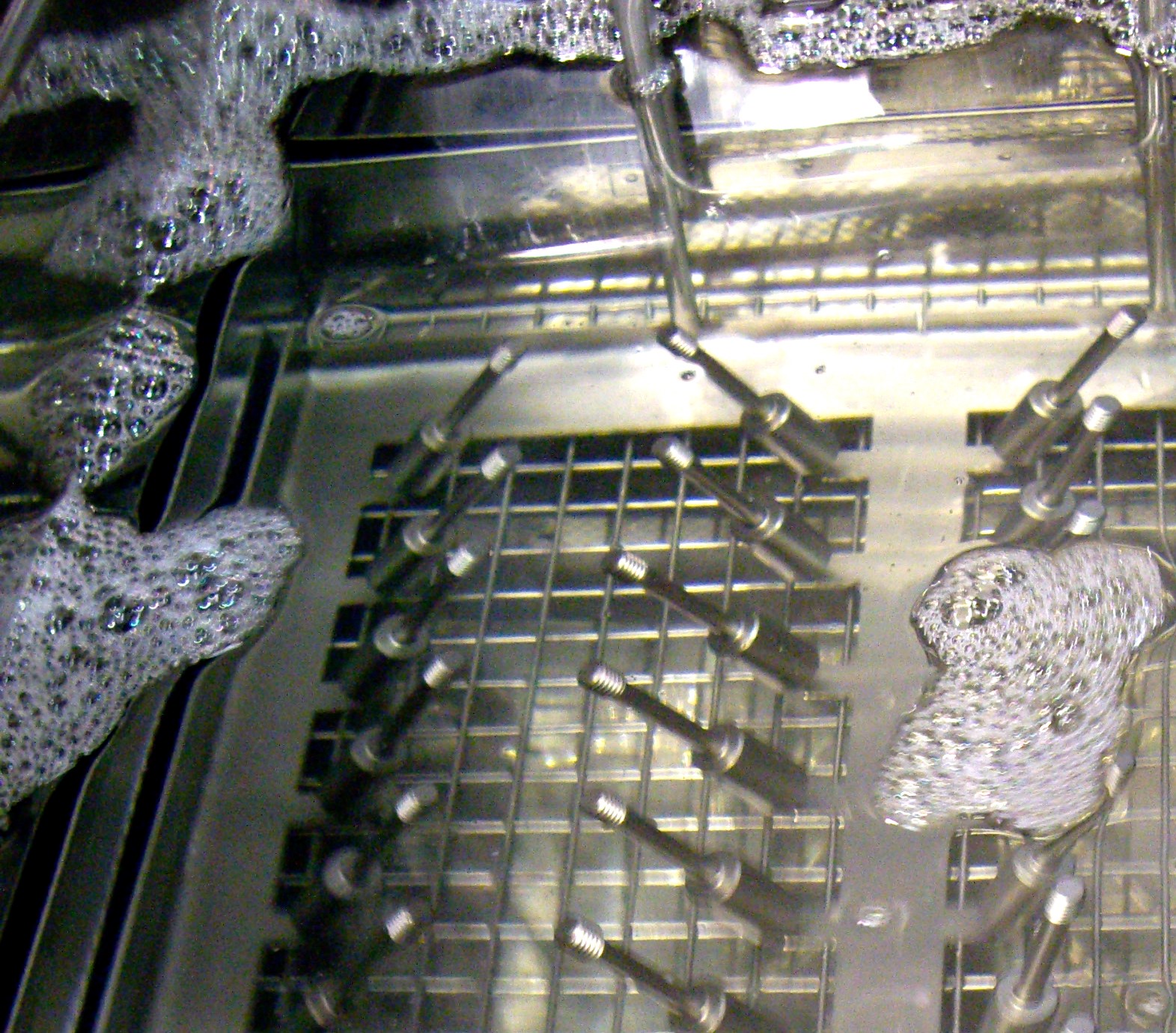

Cleaning Dept

- NElma Ultrasonic cleaning machine.

- NHygea Ultra wave ultrasonic machine

Finishing Dept

- NBead blasting cabinets,

- N Polishing machines

- N linishing m/c’s